Church pews – available in an endless variety of shapes, sizes, levels of ornamentation and build quality – all seem to have one thing in common: They’re not particularly comfortable. Not in the context of a home, that is. They’re a little too hard for lounging. A little too low for use at a table.

Some pews can be improved with a simple upholstered seat cushion. Others require a bit more work if they’re ever going to be more than a place to display pillows (and dump coats).

The pew shown here falls squarely into the “more work” category. Its form: Arched fronts and scrolled seats might be more attractive than plank styles but finding cushions with a proper fit can be challenging. Its function: The clients want to use the pew as bench seating behind their dining table but the seating height for pews can be as much as two inches too low for use at any modern table.

Here’s our solution.

BELOW: A church pew with an arched front and scrolled seat…

To address the arched front, we rough out the shape onto a basic paper template. The paper shape is then transferred to 1/4″ plywood. The plywood template can be worked as necessary to achieve a proper fit…

When we’ve got the proper fit, we transfer the 1/4″ plywood template to 1/2″ Baltic Birch plywood – a stable platform for upholstery…

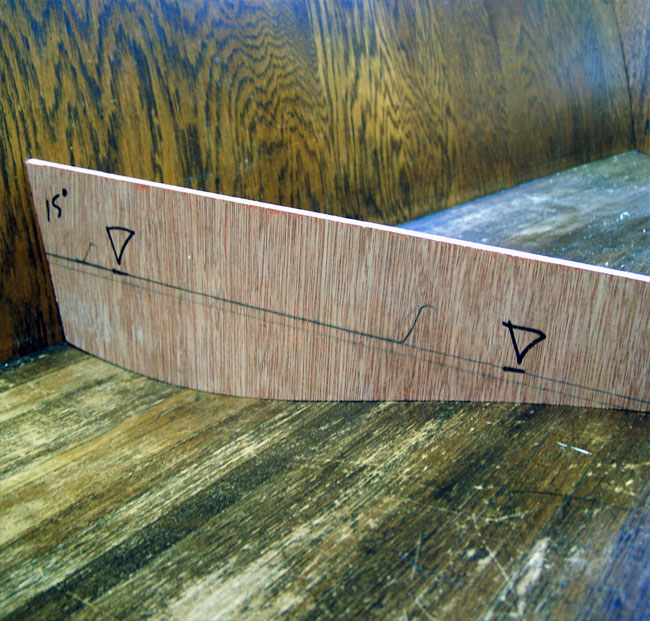

To address the scrolled seat, we trace the contour onto a 1/4″ plywood template. Note that the template has a level line indicating the location of the new seat. The bevel for the pew back is also traced. There’s a bit of trial & error here…

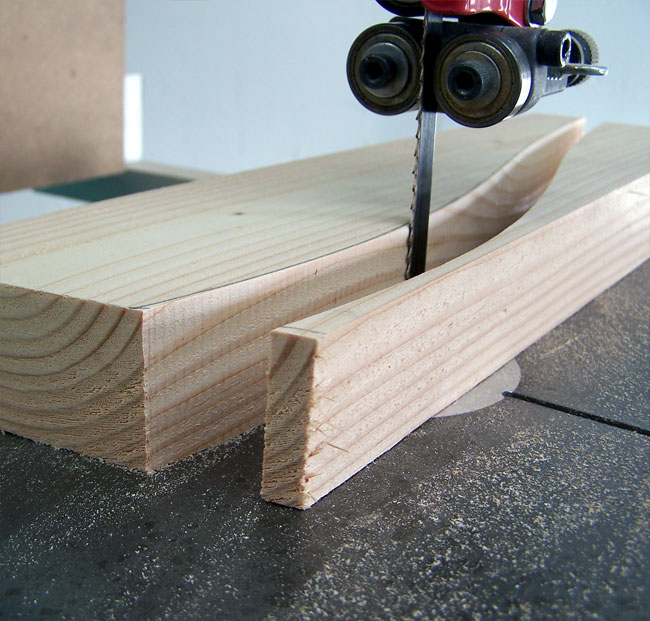

The template from the scrolled seat and bevel back are transferred to blocks and the blocks are sawn. The result is a set of ribs that echo the shape of the seat (it will make sense in the next image).

The ribs, with a shape that echoes the scrolled seat, applied to the 1/2″ Baltic Birch platform. Note that placement of the ribs follows the arch of the platform and that the ribs are notched to accept upholstery material(s)…

Now we have a form fitting, level upholstery platform for the pew. Two finger holes in the platform itself allow for easy removal…

In the upholstery shop, we apply the foam and fabric (in this case leather) and strips of felt to the base of the ribs. The felt helps to prevent the scratching and noise of wood against wood. It also helps with the fit by “absorbing” inconsistencies in the pews old wooden seat…

The final product: A church pew with a comfortable seat that’s an appropriate height for modern dining….